Industries

Pumps, Valves & Mixers

Ultimate Pump Performance

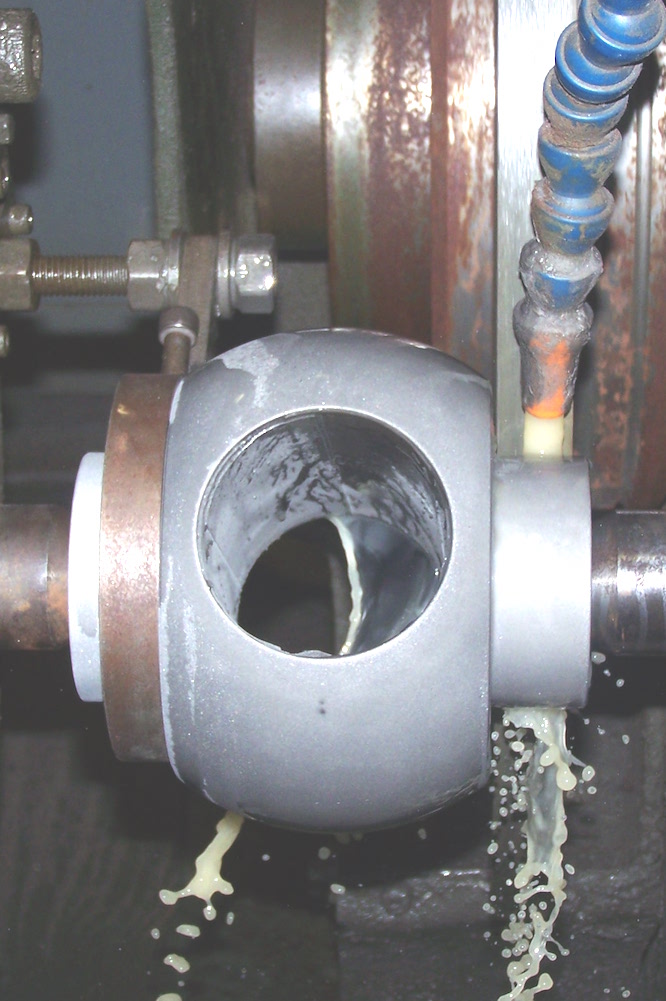

Cincinnati Thermal Spray (CTS) has been serving various pump industries for over 25 years. Types of pumps serviced include Centrifugal, Reciprocating, and Slurry pumps. CTS can make parts complete such as: wear rings, shafts, plungers, casings, sleeves, bushings and more.

In addition to making these components, we offer surface enhancements to increase performance and life.

In the pump industry, friction, corrosion, abrasion, and other forces constantly threaten deteriorating components, which can derail production and result in costly downtime. CTS engineers are experts at analyzing complex problems and developing innovative coatings to achieve and maintain peak performance. CTS specializes in coating applications for the pump industry which include, thermal spray, HVOF, Plasma Transferred Arc (PTA), and spray and fuse. Common coatings applied include: Chrome Oxide, Colmonoy 5, Colomony 6, HVOF Tungsten Carbide with a cobalt binder (WC-Co), Stellite 1, Stellite 6, Stellite 12, and others.

Our deep expertise, innovative mindset, and commitment to collaborative client partnerships make us the preeminent provider of coating application and surface technologies in the industry. Please contact us to learn more how CTS can work for you.

For more than two decades, companies like ITT Goulds, Flowserve, IMO Pumps and Weir Pumps have trusted CTS coatings to protect components inside of Industrial pumps.

For 43 years, CTS’s quality system has been established to certify our coatings to flight safety requirements. We apply the same quality system to all coatings applied in our pump industry as well.

Explore more about the various offerings from CTS in the pump industry by clicking links below to specific coatings process and components.

- PTA

- Spray and Fuse

- Fracking Seats

- Pump rebuilds

- Shafts – coated and non-coated, 120” in length +

- Impellers, coat only.

- Case rings

- Lantern Rings

- Stuffing Box Bushings, ID coat and grind

- Shaft sleeves

- Hard-faced bearings

- Throttle bushings

- Center bushings

- Valve components

- Inducers

- Seats

- Stems

- Balls

- Valve Bodies

- Diaphragms

Our Coating Technology Capabilities

CTS is your one-stop solution for all your coating technology needs.

From research and development to manufacturing and application services our team of industry experts can transform your operational challenges into enhanced production opportunities.

Engineering

Whether addressing legacy, current, or new product needs, CTS Engineering effectively and precisely addresses each client and coating process with state-of-the-art development techniques.

Component Manufacturing

Utilizing our ‘Line of Sight’ coating process, our regionally accredited manufacturing facilities contain over 30 coating booths capable of servicing an extensive range of product parts.

Quality Assembly & Finishing Systems

Our ISO9001, AS9100, NADCAP accredited facilities and certified engineering staff follow regulatory industry requirements, delivering quality data-driven coating assembly and finishing services for your business.

Core Processes

At CTS we offer a full spectrum of thermal spray coating technology application services with turnkey surface solutions that keep your products protected longer and your business operating smoother.

Pumps, Valves & Mixing Components

Stronger Parts Made to Move

With precision manufacturing capabilities and groundbreaking thermal spray technologies, CTS is your one-stop-shop for coated components and parts.

Our innovative coating services bring your product and process’ performance levels to new heights, delivering comprehensive, industry-leading applications that resist and protect against deterioration caused by erosion, corrosion, friction, and heat. Coupled with our commitment to delivering quality applications, our industry-leading coating solutions have garnered praise from loyal clients across the nation.

- Shafts

- Impeller Rings

- Case Rings

- Lantern Rings

- Stuffing Box Bushings

- Shaft sleeves

- Hard-faced Bearings

- Throttle Bushing

- Center Bushing

- Diaphragms

- Inducers

- Stems

- Seats

- Balls

- Valve Bodies

- Tail Casings

- Nozzles

Looking for more information or need a component quote?

CTS Facilities

For your convenience, we have facilities strategically located throughout the United States.

Research Center, Certifications and Approvals

Save time by using our Research Center to view next-generation coating methods and the latest coating technologies. You can also find information about our Facility Certifications and Industry Approvals.

Contact CTS

Want to learn more about CTS’ capabilities and coating solutions? Contact us today to consult directly with one of our certified engineers and discover how we can help you attain efficiency, productivity, and protection within 24 hours.