Industries

Semiconductors

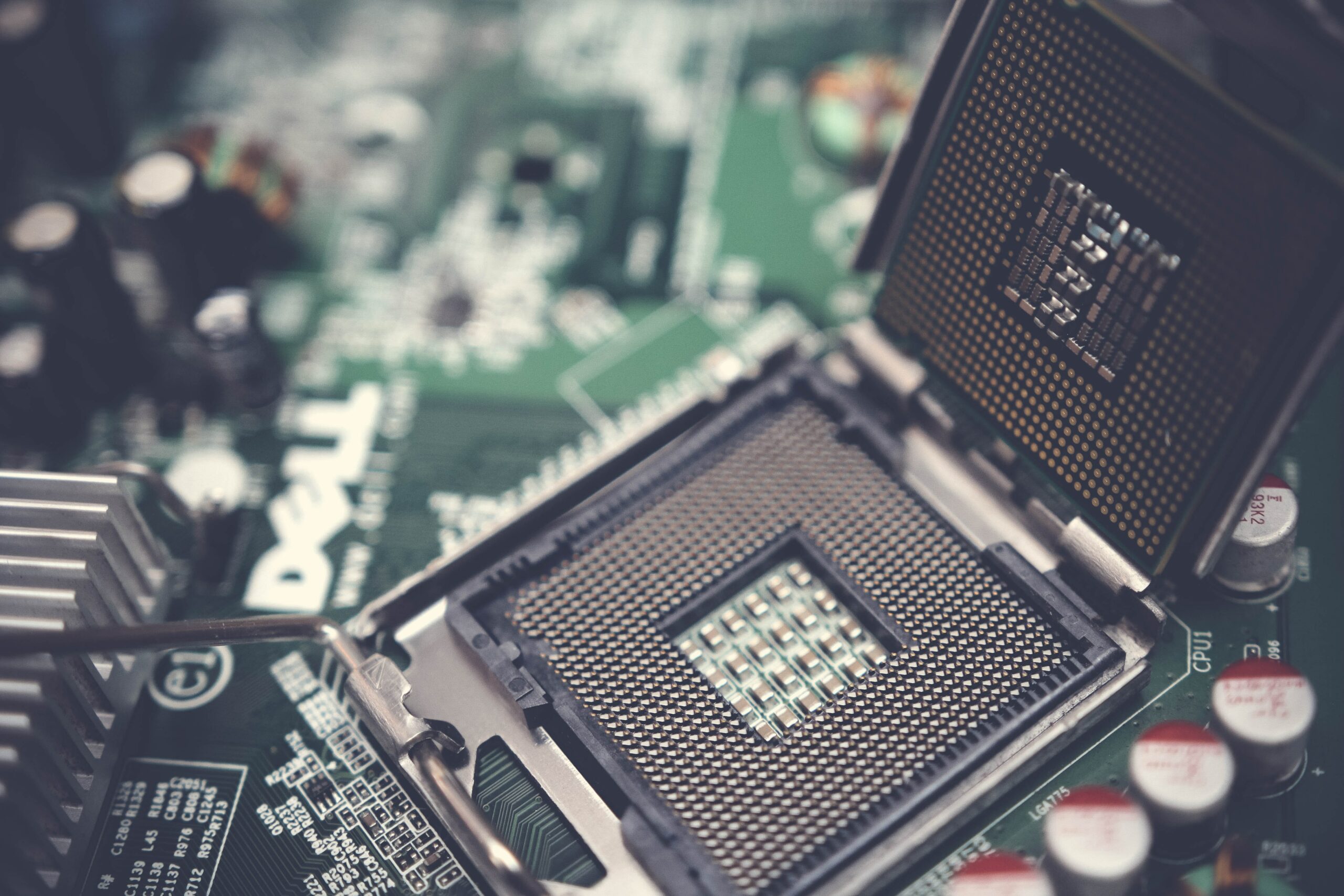

Extending the Life of Semiconductors

CTS can apply dielectric, containment/entrapment, and electrically or thermally conductive coatings to chamber components used in the manufacture of semiconductors.

The useful life of chamber components used in plasma etching processes can be extended with dielectric coatings which in-turn reduce the maintenance downtime costs.

Items such as pedestals, particle containment parts, chucks, and ion beam transmission chambers, targets, valves, gas nozzles, and fasteners can be coated with various materials to meet each specific need. Coatings can be used to prevent corrosion from gases and liquids used throughout each process. Heat sinks can be electrically isolated and protected from the chamber process(es). Chemically active coatings can be used to reduce the level of impurities and “loose” particles found in many challenging chamber processes, to galvanically protect components, or to chemically react with certain materials within the chamber.

Our Coating Technology Capabilities

CTS is your one-stop solution for all your coating technology needs.

From research and development to manufacturing and application services our team of industry experts can transform your operational challenges into enhanced production opportunities.

Engineering

Whether addressing legacy, current, or new product needs, CTS Engineering effectively and precisely addresses each client and coating process with state-of-the-art development techniques.

Component Manufacturing

Utilizing our ‘Line of Sight’ coating process, our regionally accredited manufacturing facilities contain over 30 coating booths capable of servicing an extensive range of product parts.

Quality Assembly & Finishing Systems

Our ISO9001, AS9100, NADCAP accredited facilities and certified engineering staff follow regulatory industry requirements, delivering quality data-driven coating assembly and finishing services for your business.

Core Processes

At CTS we offer a full spectrum of thermal spray coating technology application services with turnkey surface solutions that keep your products protected longer and your business operating smoother.

Semiconductor Components

High-Performance Components that Elevate Your Business

Target materials that historically have been difficult to apply via thermal spray are now able to be applied with equipment designed to prevent oxidation or nitridation of coating materials during the coating application process. Nearly 100% pure silicon and silicate coatings can also be applied to components that physically contact silicon wafers. In addition, all coating materials and processes are chemically clean and used chamber components can be stripped of coating, cleaned, and re-coated thereby reducing overall maintenance costs.

*Note: This is a partial list of parts. Contact us for a quote on your specific component.

- Pedestals

- Chucks

- Particle containment parts

- Ion beam transmission chambers

- Targets

- Valves

- Gas Nozzles

- Fasteners

Looking for more information or need a component quote?

CTS Facilities

For your convenience, we have facilities strategically located throughout the United States.

Research Center, Certifications and Approvals

Save time by using our Research Center to view next-generation coating methods and the latest coating technologies. You can also find information about our Facility Certifications and Industry Approvals.

Contact CTS

Want to learn more about CTS’ capabilities and coating solutions? Contact us today to consult directly with one of our certified engineers and discover how we can help you attain efficiency, productivity, and protection within 24 hours.