Industries

Steel

Coating Technology That Can’t Be Beat

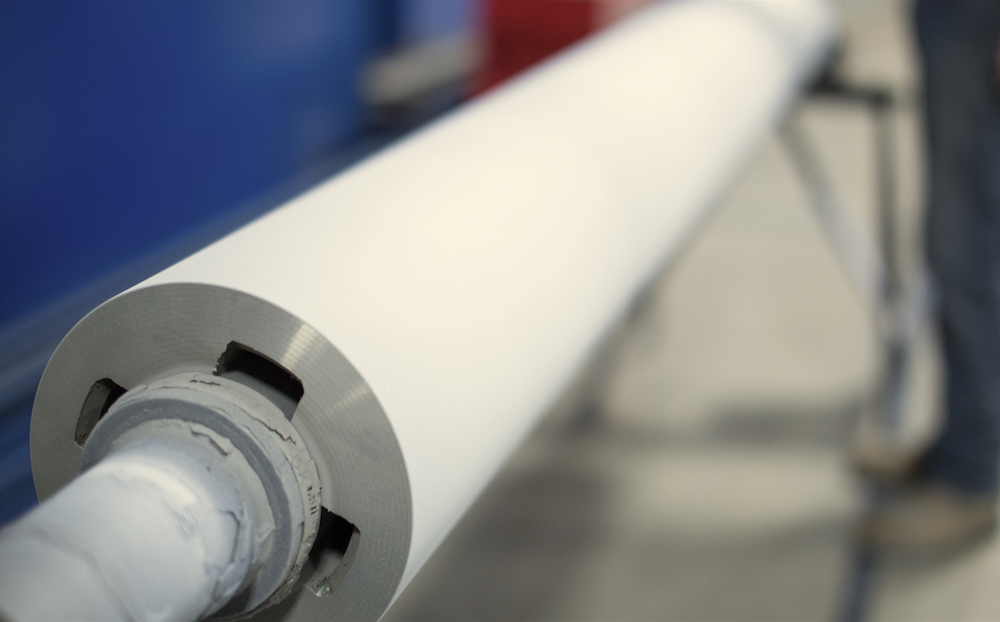

When it comes to meeting expectations, CTS’s coating technology sets the industry gold standard for galvanization and aluminizing continuous strip lines throughout steel mills across America.

Our high-performance galvanized coatings for molten Zinc and Aluminum are second to none and when combined with our precision coating processes, effectively deter dross pick up within your mill’s pots. The results? A custom coating solution that keeps your mill operating at peak performance.

In addition to keeping your mill’s products and operations running smoothly, we offer full repair services for all your used pot equipment including:

- Roll inspection report generation

- Machining refurbishment of roll faces

- Full journal repair

- Reapplication of roll coatings

Our Coating Technology Capabilities

CTS is your one-stop solution for all your coating technology needs.

From research and development to manufacturing and application services our team of industry experts can transform your operational challenges into enhanced production opportunities.

Engineering

Whether addressing legacy, current, or new product needs, CTS Engineering effectively and precisely addresses each client and coating process with state-of-the-art development techniques.

Component Manufacturing

Utilizing our ‘Line of Sight’ coating process, our regionally accredited manufacturing facilities contain over 30 coating booths capable of servicing an extensive range of product parts.

Quality Assembly & Finishing Systems

Our ISO9001, AS9100, NADCAP accredited facilities and certified engineering staff follow regulatory industry requirements, delivering quality data-driven coating assembly and finishing services for your business.

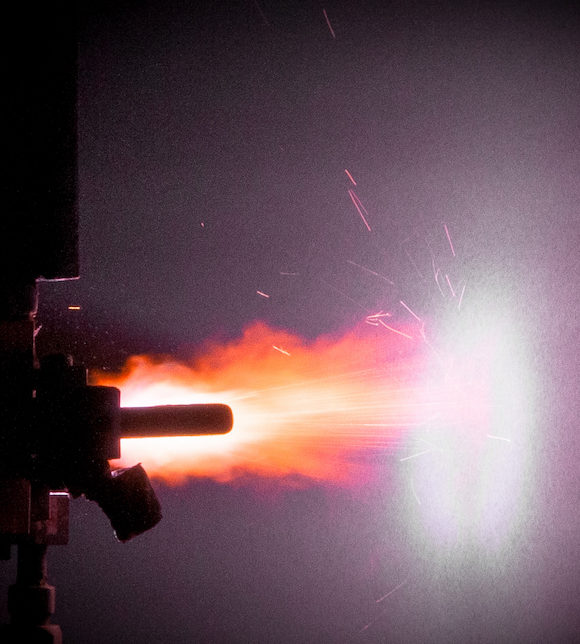

Core Processes

At CTS we offer a full spectrum of thermal spray coating technology application services with turnkey surface solutions that keep your products protected longer and your business operating smoother.

Steel Industry Applications

Thermal Spray Solutions for the Steel Industry

CTS also offers a wide range of wear and corrosion resistant thermal spray-based coatings to protect your components and surfaces in every part of the mill.

- Temper Mills

- Tandem Mills

- Tin Mills

- Bridle Rolls

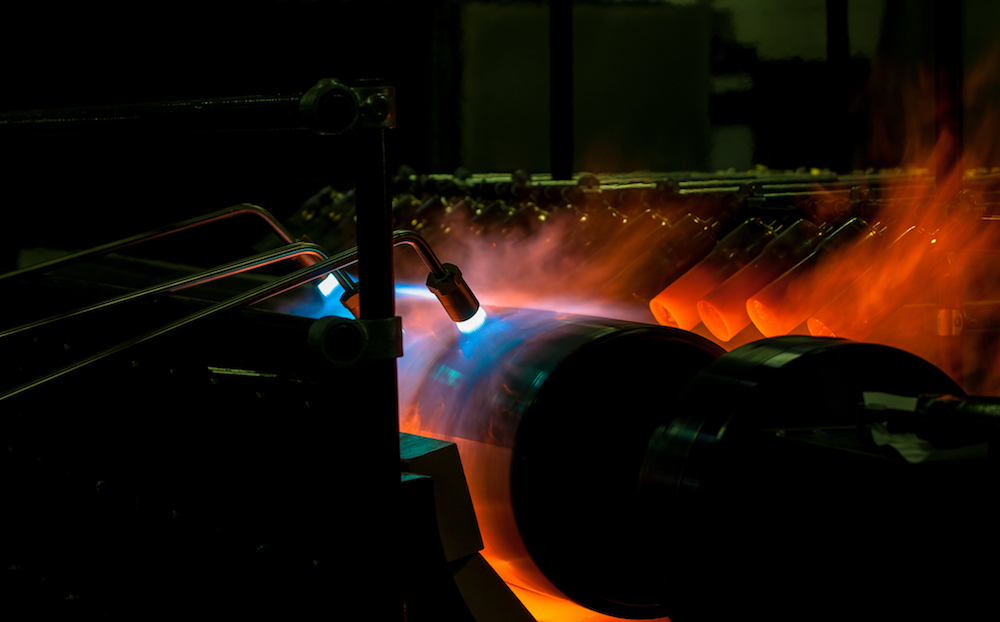

- Furnace Rolls

- Pickling Lines

- Annealing Lines

- Slitting Lines

Mills, Rolls & Lines

- Galvanize

- Galvaneal

- Aluminize

Hot Dip Coatings

- Continuous Caster

- BOF

- LMF

Steel Making

Technical Service Expertise

Servicing the Steel Industry with Unmatched Technology

- PTA (Plasma Transferred Arc) Cladding

- OD and ID Surface Protection

- Pro-Mic©Electronic-Accurate, Reliable Roll Surface Profiling

- Journal & Bushing Metallurgies

- Corrosion & Wear Protection

- Custom Surface Finishing to meet Unique Customer Requirements

- Surface Finish at 5-10 Ra Increments

- Custom Roll Profiling (Crowning)

- Customer Materials & Application Driven Technical Solutions

Looking for more information or need a component quote?

CTS Facilities

For your convenience, we have facilities strategically located throughout the United States.

Research Center, Certifications and Approvals

Save time by using our Research Center to view next-generation coating methods and the latest coating technologies. You can also find information about our Facility Certifications and Industry Approvals.

Contact CTS

Want to learn more about CTS’ capabilities and coating solutions? Contact us today to consult directly with one of our certified engineers and discover how we can help you attain efficiency, productivity, and protection within 24 hours.