Core Processes

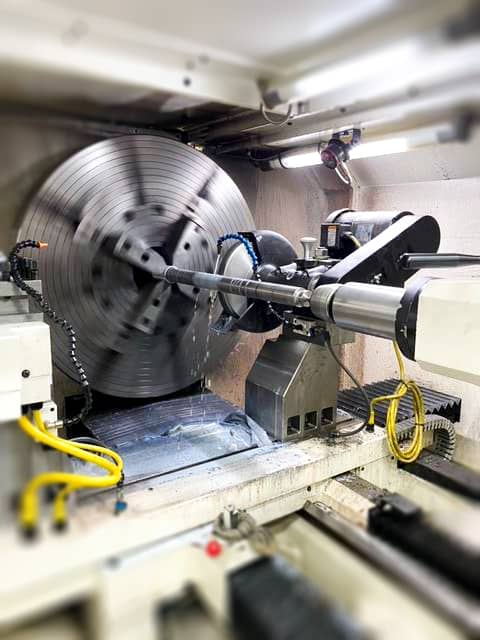

Precision Machining and Grinding

Utilizing our automated CNC precision machining and grinding services—when coupled with our thermal spray coating processes—provides the foundation for your project’s new component manufacturing or remanufacturing needs.

Located across our enterprise facilities, our state-of-the-art CNC turning centers house our quick turn machining and grinding “cells” that each play a vital role in supporting our new and repair parts market services. From inside diameter (ID) and outside diameter (OD) grinding, to CNC machining, our precision manufacturing processes help make us your one-stop-shop for all your thermal coating service and product finishing needs.

Our Capabilities

- Mirror Finish Grinding & Polishing (<4Ra)

- Inside Diameter (ID) & Outside Diameter (OD) Grinding

- Internal Grinding

Precision Machining

CTS offers full-service CNC precision machining for all your customized components and parts.

Supported by our team of professionally certified engineers, our CNC machining processes utilize pre-programmed computer software to control the range of our complex machinery and factory tools, including grinders, lathes, mills, and routers. Our manufacturing processes work by leveraging the various functions of these machines to pre-program their behaviors such as speed, feed rate, and coordination to run in repetitive, predictable cycles to produce the desired cuts for your signature parts or components.

All of our CNC machining processes meet and exceed all industry-standard regulations and market requirements, providing you with cost-effective manufacturing solutions that drive real results. And with a dedicated team of specialists located at each of our enterprise facilities, we’ll work directly with you to develop a customized CNC machining solution that’s tailored perfectly for your project’s material needs, delivery timeframe, and logistics.

Precision Grinding

CTS also offers full-service CNC precision grinding to add the finishing touch to all your product’s finite parts and components.

Central to our core processes, our CNC grinding services leverage a variety of precision metal grinding techniques and abrasive subset cutting methods to remove small excess materials from your product—helping create custom finishes or tight tolerance dimensions on your application surfaces. Utilized for the hard-fine machining of parts, our automated grinding machines increase production performance during our finishing process and can achieve the highest material removal rates, yielding even shorter delivery times and satisfactory quality.

With a variety of metal grinding options available with varying benefits, selecting the proper application for your product isn’t always easy.

That’s why our team of professionally certified engineers and industry experts is here to help you choose a precision metal grinding process that’s right for your product. We’ll assist you in determining your part dimensions compatibility with specific grinding processes, your part’s tolerance, and impact on its functionality, your production and capacity needs, and the desired surface quality you’re looking to achieve.

And with automated loading facilities available nationwide, our dedicated team of manufacturing specialists will work directly with you to deliver a modern, efficient finish for all your parts and components.

Want to learn more about CTS’ precision machining capabilities and grinding services?

Contact us today to consult directly with one of our representatives or certified engineers and discover how we can help you attain efficiency, productivity, and protection within 24 hours.

Industries We Serve

Our diverse team of thermal spray coating specialists offers unparalleled expertise across a wide range of industries

Aerospace

Automotive

Industrial

Power Generation

Oil & Gas

Steel

Wire & Cable

Medical

Marine

Pumps, Valves & Mixers