Core Processes

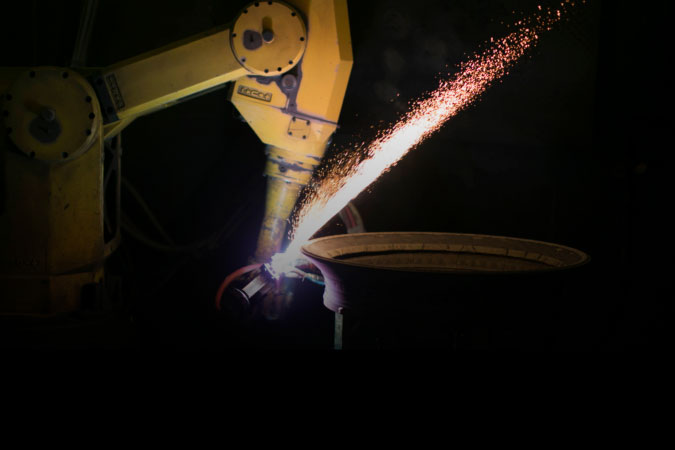

High-Velocity Oxygen & Air Fuel Coating

High-Velocity Oxygen Fuel and High-Velocity Air Fuel Coatings

High-velocity fuel coating is a thermal spray coating process, which is used to enhance or restore a component’s surface.

This surface engineering technique better enables the life extension of equipment by improving erosion and wear resistance and adding corrosion protection.

High-Velocity Oxygen Fuel (HVOF) High-Velocity Air Fuel (HVAF) processes address

- Wear and Erosion

- Abrasion

- Adhesive Wear

- Cavitation

- Hard Chrome Replacement

- High Temperature Environments

- Corrosion Resistance

- Atmospheric Environments

- New Part Manufacturing

- Cathodic Protection

- Chemical Environments

- Friction Engineering for Fretting

- Galling

- Anti-skid/Traction

- Tribological Coatings

- Dimensional Restoration of parts requiring repair

CTS has a long history of working with its clients to improve their parts and enhance durability using High-Velocity Fuel Coatings.

Our approach to combustion thermal spray and high-velocity fuel coating is unique because we are experts in all coating technologies. We are constantly working towards developing new and better outcomes.

High-Velocity Oxygen Fuel Coating (HVOF) offers a tailored solution to your product’s needs versus other thermal spray coatings. With over 400 thermal spray materials available, there are numerous options to create the perfect high-velocity surface coating for your equipment needs.

Our team of professionally certified engineers and industry experts can assist you in selecting the right materials for your HVOF/HVAF coating.

Want to learn more about CTS’ capabilities and high-velocity oxygen fuel and high-velocity air fuel coating solutions?

Contact us today to consult directly with one of our representatives or certified engineers and discover how we can help you attain efficiency, productivity, and protection within 24 hours.

Industries We Serve

Our diverse team of thermal spray coating specialists offers unparalleled expertise across a wide range of industries

Aerospace

Automotive

Industrial

Power Generation

Oil & Gas

Steel

Wire & Cable

Medical

Marine

Pumps, Valves & Mixers