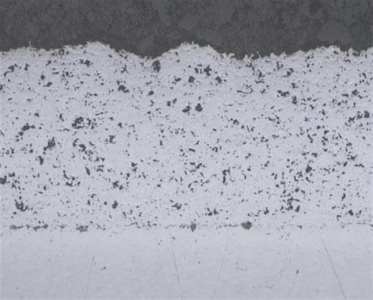

Standard Density 88/12 Tungsten Carbide Cobalt

CT2104-1

CT2104-1 an 88% tungsten carbide/12% cobalt coating applied using the plasma spray process. It is a high quality coating for low temperature wear resistance, highly recommended for resistance to particle erosion, hard surfaces, fretting and abrasive grains.

Typical Properties

Nominal Composition:

88% Tungsten Carbide, 12%

Bond Strength:

6,500 psi

Coating Porosity:

Less than 2%

Coating Hardness:

DPH300 900-1100

As-sprayed Surface Roughness:

250-400 Ra

For the Following Applications:

CT2104-1 is used in applications such as aircraft flap tracks, aircraft turbine shafts, exhaust fans, concrete mixing equipment, and plug gages.

Finishing

Finish CT2104-1 by grinding with diamond wheels. CT2104-1 should be wet ground. CTS can recommend grinding parameters if needed.

Specifications

CTS-2104-1 meets the following specifications: