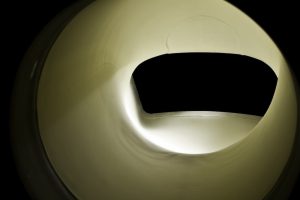

Gas Turbine Thermal Barrier Coating in Combustion Liners

In a typical industrial gas turbine used to provide electric power as peaking units, and sometimes even as baseload units, the actual burning of the fuel takes place in a combustion liner or combustion basket. These components are constantly exposed to a severe service environment and must stand up to:

- Repeated thermal cycling

- Extremely high temperatures

- Corrosion from elements in the fuel

- Erosion from material introduced by either the fuel or air used in combustion

Coating Selection:

Coating Selection:

Most modern gas turbines utilize thermal spray coating technology to maintain performance of these components. Coatings for combustion liners are normally specified by the turbine manufacturer. The gas path of these parts are coated with a thermal barrier coating, typically consisting of a metallic layer, called the bond coat, made of a material referred to as an MCrAlY – an alloy of metals like Nickel or Cobalt (or some combination thereof) and Chromium, Aluminum and Yttrium. This layer is very stable at high temperature and protects the base alloy of the component from the hot gas produced in the combustion process.

Once this bond has been applied, a layer of ceramic is applied directly on top. This ceramic top coat is commonly made from various forms of zirconium oxide. This two layer system, applied using the plasma spray process, protects the metal of the combustion liner from hot gas corrosion, erosion and thermal cycle fatigue. In addition to the thermal barrier, wear resistant coatings are often used to protect wear areas of the liners. These coatings are either chrome carbide nickel chrome or one of a series of alloys designed for high temperature wear resistance.

CTS has coated thousands of combustion liners and buckets, both OEM components and repair components. Our long history of developing proven industry solutions that deliver superior field performance is supported by a high level of technical excellence. CTS is approved by all major manufacturers of industrial gas turbines.

To learn more about CTS capabilities, contact us to consult with a CTS Engineer and we will respond within 24 hours.