Wire & Cable

Request QuoteEffective Ways to Stop Deterioration

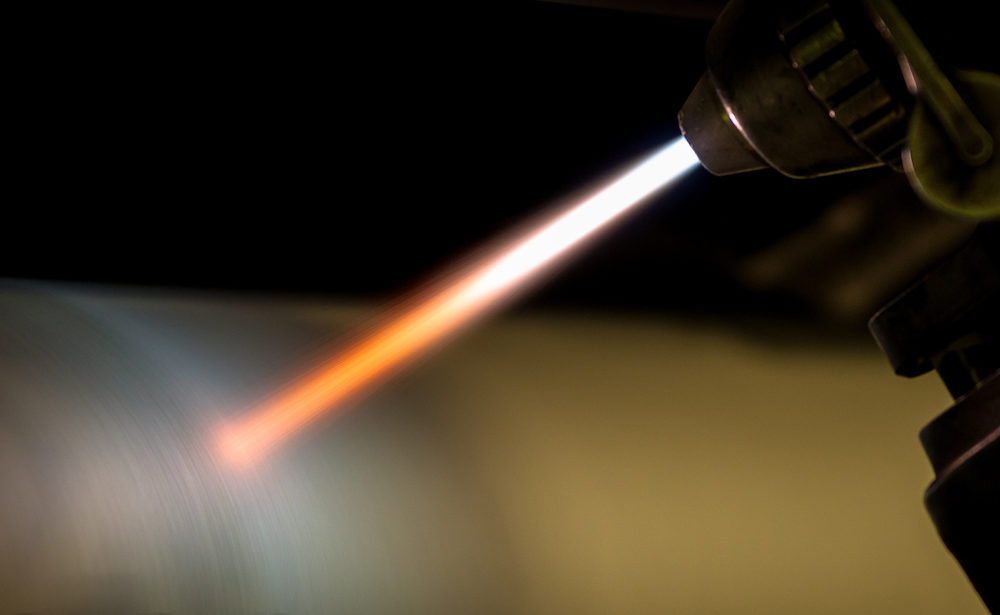

Expanding the Limits of Protective Coatings

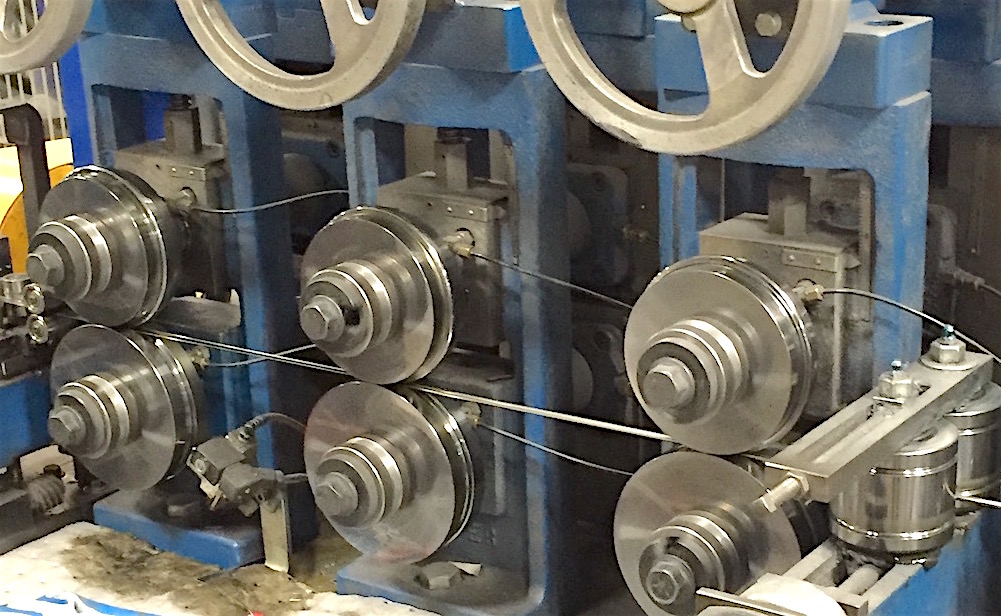

The wire drawing industry is constantly battling severe component wear challenges.

At CTS, we realize that each of your wiring machines is different and all wire and cable require an effective way to stop deterioration caused by destructive forces.

Building on our proven success in developing and delivering wear-resistant coatings in this market, we are excited to introduce our next-generation wear-resistant coatings portfolio for wire drawing machines. When you partner with CTS, we provide you with the latest surfacing applications designed to push the boundaries of your existing Tungsten Carbide coatings and legacy system solutions.

In addition to our custom coating solutions, we also offer product part refurbishment and work closely with you to develop a custom-tailored process that works for your wire drawing needs.

Wire & Cable Components

Wired Component Protection that Lasts

As a recognized leader in the commercial and industrial sectors, CTS develops innovative coating solutions for every possible surface application. We service a variety of markets including paper roll manufacturers, machinery rebuilders, and power utilities, delivering protective coatings, adhesives, and surface solutions that extend the structural durability and life of your products.

- Capstans

- Pulleys

- Blocks

- Rollers

- Rings

- Guides

Our Markets

Innovative & Unique Coating Services

Every market we serve has a specific combination of products, parts, processes, and challenges.

Our technological expertise along with a thorough understanding of your industry’s complexities is critical to identifying existing and potential problems with your product or processes. We then leverage our research and collected industry data to create opportunities and custom coating solutions to improve your product’s overall performance.