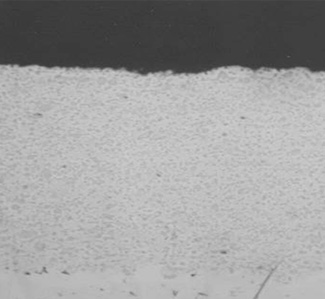

High Density 83/17 Tungsten Carbide Cobalt

CT-2110-2

CT2110-2 an 83% tungsten carbide/17% cobalt coating applied using the HVOF spray process. It is very hard, dense, tough coating exhibiting high bond strength, excellent fret wear resistance, good abrasive wear resistance, good impact wear resistance and can be finished to a very fine finish.

Typical Properties

Nominal Composition:

83% WC, 17% Co

Bond Strength:

>10,000 psi

Coating Porosity:

Less than 1%

Coating Hardness:

DPH300 >950

As-sprayed Surface Roughness:

140-190 Ra

For the Following Applications:

CT2110-2 is used in applications such as aircraft VGV bushings, aircraft shaft journals, aircraft flap tracks, wire drawing blocks, oil field sucker rods, and labyrinth seal teeth.

Finishing

Finish CT2110-2 by grinding with diamond wheels. CT2110-2 should be wet ground. CTS can recommend grinding parameters if needed.

Specifications

CT-2110-2 meets the following specifications:

GEAE:

B50TF167A

Rolls Royce:

EMS 39660

RRMS:

40015